- Find the best coating solution

Emisshield® is the only leading standard for High Emissivity Coatings with NASA origin

Our Emisshield products are high emissivity coatings with heat re-radiation capabilities extending over a wide temperature range up to 3,100°F (1,700°C). Emissivity is the measure of a body’s ability to emit or absorb energy when compared to a perfect black body. Emissivity is measured on a scale from zero to one, one being a perfect black body. All Emisshield Products have an emissivity value between 0.85 and 0.95.

What does that mean? Better combustion, energy savings, production increases, minimized downtime, extended life of the substrate and an overall more efficient operation.

for Furnaces, kilns, fired heaters, heat treatment systems and OEM parts

Unmatched Quality and Performance

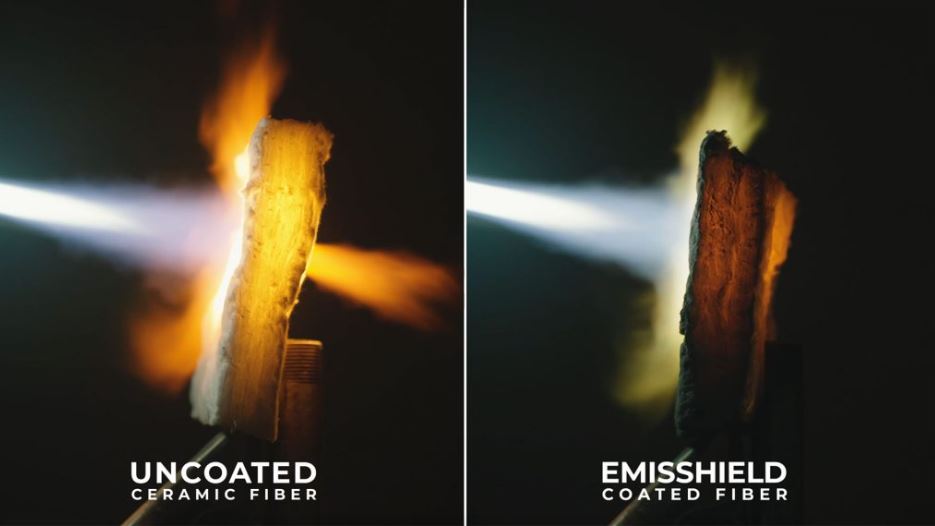

Ceramic fiber burn through test

Emisshield sintered metal coating

Ceramic fiber coating

Conserve Energy. Enhance Production

Emisshield provides the highest quality, energy-saving products and technologies to all industry market areas around the world. With company CRESS B.V., the European Application partner of Emisshield and specialized in refractory works, we are driving a new era of reduced energy costs, improved combustion and reduced carbon intensity across the full spectrum of heat transfer and high-energy applications.

Reference documents for Download

Presentations

MSDS

SDS-Ceramic_Refractory_Coatings-AT-de-20_12_2023

SDS-Ceramic_Refractory_Coatings-BE-nl-20_12_2023

SDS-Ceramic_Refractory_Coatings-BG-bg-20_12_2023

SDS-Ceramic_Refractory_Coatings-CH-de-20_12_2023

SDS-Ceramic_Refractory_Coatings-CH-fr-20_12_2023

SDS-Ceramic_Refractory_Coatings-CH-it-20_12_2023

SDS-Ceramic_Refractory_Coatings-CZ-cs-20_12_2023

SDS-Ceramic_Refractory_Coatings-DE-de-20_12_2023

SDS-Ceramic_Refractory_Coatings-DK-da-20_12_2023

SDS-Ceramic_Refractory_Coatings-ES-es-20_12_2023

SDS-Ceramic_Refractory_Coatings-FI-fi-20_12_2023

SDS-Ceramic_Refractory_Coatings-FR-fr-20_12_2023

SDS-Ceramic_Refractory_Coatings-GR-el-20_12_2023

SDS-Ceramic_Refractory_Coatings-HR-hr-20_12_2023

SDS-Ceramic_Refractory_Coatings-HU-hu-20_12_2023

SDS-Ceramic_Refractory_Coatings-IT-it-20_12_2023

SDS-Ceramic_Refractory_Coatings-NL-en-20_12_2023

SDS-Ceramic_Refractory_Coatings-NO-no-20_12_2023

SDS-Ceramic_Refractory_Coatings-PL-pl-20_12_2023

SDS-Ceramic_Refractory_Coatings-PT-pt-20_12_2023

SDS-Ceramic_Refractory_Coatings-RO-ro-20_12_2023

SDS-Ceramic_Refractory_Coatings-RS-sr-20_12_2023

SDS-Ceramic_Refractory_Coatings-SE-sv-20_12_2023

SDS-Ceramic_Refractory_Coatings-SI-sl-20_12_2023

SDS-Ceramic_Refractory_Coatings-SK-sk-20_12_2023

Project Questionaire

Case Studies

Batch kiln – Institut für Ziegelforschung, Essen, Germany

Tunnel kiln – Ziegelwerk Bellenberg, Bellenberg, Germany

Tunnel kiln – Walther Dachziegel, Langenzenn, Germany

Batch Reheat Furnace – FRISA Steel, Mexico

Tunnel kiln – Creaton, Guttau, Germany

Tunnel kiln – Jakobi Tonwerke, Bilshausen, Germany

Roller kiln – Steuler Group, Bremerhaven, Germany

Pusher furnace – CELSA, Mo i rana, Norway

Melding/Holding furnace – Vedanta Aluminium, Odisha, Indien

Sustainability

Emisshield designed and developed a line of high emissivity coatings to specifically assist industrial heating processes with the reduction of their carbon footprint by saving energy. The sustainability product line enhances the overall performance of your kiln and assists you in producing the same amount of products while using less energy. Globally, companies are introducing new ways to achieve these measures and Emisshield is here to help. Typically paying for itself within a year and boasting a product lifespan of 5 to 7 years, more than 40 furnaces and kilns across Europe have been coated over the past two years, with a proven average energy savings of +-5%.

Space Technology Hall of Fame

The technology behind the coating was invented at NASA’s Ames Research Center in the early 1990s as a protective coating for use on spacecraft and licensed to Emisshield, Inc. in 1996. Meeting the criteria of adapting space technologies into commercial products that improve quality of life on Earth, the president and CEO of Emisshield, Dr. John Olver became the 85th individual Inductee into the Space Technology Hall of Fame.

Conserve Energy, enhance Production

Whether you are forging steel or cracking molecules, Emisshield Inc. has the technology and resources to take on your biggest challenges and make them a thing of the past. To maximize your results, we don’t just sell you the coating, we analyze your challenges, determine the right application, supply you with the right space certified technology and have it installed by professional Emisshield Installers.

Emisshield has designed several products for refractory, ceramic fiber and metal surfaces since obtaining the technology. These advancements provide our customers with the best products for their specific situation.

Interesting publications

Featured Cases & Articles

Emisshield®

CELSA Nordic, Norway

EMISSHIELD BENEFITS statement by CELSA Nordic:

“The weighted average we have got as a result of our analysis is 5.55% improvement in the post-coating period compared to the pre-coating period.”

Emisshield®

Advertorial:

Experiences with Emisshield® High Emissivity Coatings in tunnel and roller kilns

Experiences with Emisshield® High Emissivity Coatings in tunnel and roller kilns

Emisshield®

TCKI, the independent Dutch research institute for the brick industry, confirms energy savings of 3.1% and more even heat distribution in the kiln.

Gas consumption for 2024 includes the start-up phase and recipe adjustments.

Better heat transfer and thus a lower required kiln temperature result in lower fuel consumption and fewer CO₂ emissions.

Case studies

Prev

Next